Product center

Product center

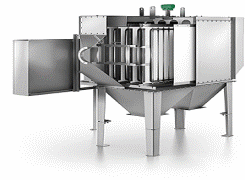

WD series electrostatic precipitator

Compared with other dust collection equipment, WD horizontal electrostatic dust collector has the advantages of less investment, advanced technology, large smoke volume, high dust removal efficiency, low pressure loss, low operating costs, power consumption, simple maintenance, etc., and is widely used in metallurgy, building materials, electric power and other industries for material recovery and gas purification.

Working principle

Compared with other dust collection equipment, WD horizontal electrostatic dust collector has the advantages of less investment, advanced technology, large smoke volume, high dust removal efficiency, low pressure loss, low operating costs, power consumption, simple maintenance, etc., and is widely used in metallurgy, building materials, electric power and other industries for material recovery and gas purification.

Working principle

WD type horizontal electrostatic dust collector is a device that uses the principle of static electricity to purify gas. After high voltage direct current is passed in its electrode system, a large number of electrons and ions are generated between the electric fields. When the dusty gas enters the electric field, under the action of these electrons and ions, all the dust will be charged at a very fast speed and rapidly extend to the electrode of its opposite polarity under the action of the electric field. Finally, the charge is released and adsorbed on the electrode, and the dust is removed to the lower ash hopper after vibration, and the dust is discharged to the machine through the bottom ash discharge device, and the purified gas is finally discharged into the atmosphere, completing the gas purification process.

Conditions of use

1. The maximum allowable flue gas temperature is 250℃, and the minimum flue gas temperature shall not be lower than 20℃ dew point temperature of flue gas.

2, the smoke pressure should be between 3000Pa and +500Pa.

3. The smoke shall not contain substances that can cause serious corrosion of the equipment.

4, the dust in the flue gas is less viscous to the electrode.

5, the smoke should not contain flammable and explosive substances (except for explosion-proof and fire-fighting devices).

6, the dust specific resistance in the flue gas should be between 104~1011 ohms · cm.

7, such as single use, should be set up bypass flue, so that the dust collector can stop for maintenance.

Main technical parameters and specifications

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share

INQUIRY

Add Successfully

幸福宝在线观看環保

幸福宝在线观看環保