Product center

Product center

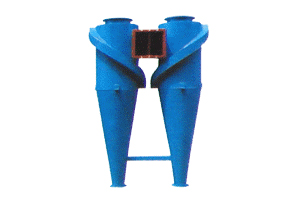

CLK diffused cyclone

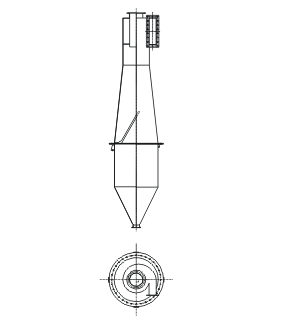

The structure of the dispersive cyclone dust collector is characterized by the cone turning into an inverted cone and the reflection screen fixed by gas at the lower part, which can avoid the secondary dust collection caused by the enrolling and enrolling of the upswirl airflow returning from the upper part of the dust, so it can improve the dust removal efficiency. On the other hand, the cross section of the inverted cone is smaller and larger, so that the swirling velocity of the dusty gas in

The structure of the dispersive cyclone dust collector is characterized by the cone turning into an inverted cone and the reflection screen fixed by gas at the lower part, which can avoid the secondary dust collection caused by the enrolling and enrolling of the upswirl airflow returning from the upper part of the dust, so it can improve the dust removal efficiency. On the other hand, the cross section of the inverted cone is smaller and larger, so that the swirling velocity of the dusty gas in the surrounding boundary layer is lower, which can also reduce the backmixing and reduce the wear of the wall.

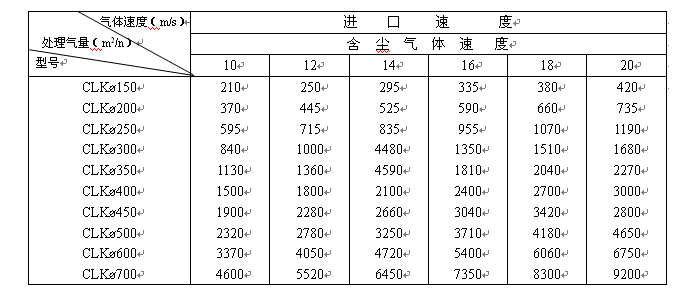

(1) The performance of the dispersive dust collector The main performance of the CLK (dispersive) type cyclone dust collector is listed in the following table. The main feature of the diffusible dust collector is that the air flow organization in the dust collector is improved, and its structure is simple and convenient to manufacture. The adaptability of dust concentration is good. The inlet concentration of the dust collector varies in the range of 2 ~ 200g/m3, and the dust removal efficiency does not fluctuate much. The dispersive divider is more suitable for capturing powder with a particle size greater than 10um, and its total dust removal efficiency can reach 88% ~ 92%, and the airflow resistance in the dust collector is about 900 ~ 1200Pa. The main disadvantage of the dust collector is the wear problem of the dust collector cylinder, although the lower part of the dust collector adopts the inverted cone structure, which reduces the cone wear, but the outer side of the imported simum shell is still easier to wear, affecting the long-term operation of the dust collector, so anti-wear measures should be added to the inner wall of the upper cyclone.

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share

INQUIRY

Add Successfully

幸福宝在线观看環保

幸福宝在线观看環保